Interactive Simulation of Pipeline Network

Simulator

The pipeline simulation system developed by GB Simulation Technology consists of a rigorous model of the pipeline and associated equipment. It allows interactive communication through a simple menu-driven user-interface. Users can create various operating scenarios, execute simulation runs, monitor their progress and examine results, under one operating system. Various operating scenarios can be created by calling up relevant screens containing schematic diagrams of the process, and subsequently the results can be analysed by paging through a series of screens with the help of self-explanatory mouse- activated menus.

Applications

An earlier version of the simulator was installed in the following industrial applications.

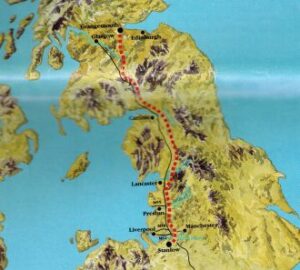

The North Western Ethylene Pipeline Interactive Simulation System (NIS) was developed by GB Simulation Technology in 1992. The North Western Ethylene Pipeline (NWEP), consisting of approximately 413 km of 10-inch pipes, runs from the BP Chemicals Limited terminal at Grangemouth in Strathclyde to the Shell Refinery at Stanlow in Cheshire. The NWEP is the final link between Shell’s oil and gas fields in the North Sea and its petrochemical complexes in Cheshire.

The route of the pipeline traverses several ranges of hills, the highest being in the vicinity of Crawford in the Lowther Hills, where the pipeline reaches a height of about 450 meters above sea level. There are 24 rail, 250 road, 239 river and 11 canal crossings.

Compressor stations are located at Grangemouth and 185km downstream near Carlisle, before the pipeline passes over the Cumbrian Mountains. Mainline block valves are located at approximately 16km intervals. Metering stations are located at Grangemouth and at Stanlow. The installations at Stanlow incorporate pressure reduction and both high pressure and low pressure distribution systems to consumers in the Stanlow area.

The pipeline operates between 60 and 95 barg and has capacity to deliver dense-phase ethylene 610,000 tonnes per year.

The NWEP was the first pipeline project to be subject to the 1989 environmental and safety regulations, and consequently the design and construction took place and operations are carried out with environmental safety as the highest priority.

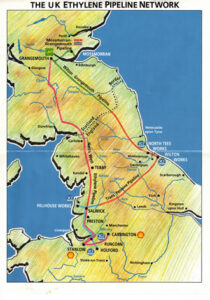

This interactive system was also adapted for simulating the UK Ethylene Pipeline Network which includes two major ethylene pipelines, the Trans Pennine Ethylene Pipeline and the Wilton Grangemouth Ethylene Pipeline.

Simulator Architecture

The earlier version of the simulator for ethylene pipelines developed in 1992 is described here. At the heart of the system are two software packages: the MICRO-CHEM Process Simulator and Process Data Management System, and EPROP, a validated ethylene thermodynamic and transport property prediction package.

MICRO-CHEM is a combination of a process simulator and a data management system. The process simulator models a wide range of unit operations, equipment, pipes and fittings, and is solved by fundamental rules of mass and heat transfer supported by software incorporated with a finite-volume compressible flow mass and thermal modeller and a numerical solver.

The data management section of MICRO-CHEM maintains a database of project information and simulation data, and allows communication with its own simulator as well as other packages. Process schemes can be described in three ways. The easiest way is by using a series of screen menus which have been styled to follow the format of standard process data sheets. Alternatively, the user can write a data file in a free format input language. Thirdly, information can be supplied as database files, which are accepted in several different formats provided by the popular database management systems. Once a simulation run is completed its results are transferred to the database, which are then available for further analyses.

The ethylene properties are highly sensitive to pressure and temperature in the supercritical region. Process calculations based on adiabatic processes, and those involving pipe pressure losses, for example, have been shown to require fluid properties such as density, enthalpy, entropy and viscosity estimated to a high degree of accuracy, in order that close agreement is retained between predicted and observed performances. Specifically, in the area of line pressure loss estimations such calculations are performed a large number of times for every pipe element. A small error gets enlarged and carried forward as calculations are performed over the whole length of the line, resulting in considerable deviations from the observed values. MICRO-CHEM employs an iterative procedure that updates pressure, temperature and physical properties for every element until all errors are eliminated, and in this respect EPROP has proved to be an important and necessary constituent of the simulator system.

The pipe flow rarely attains true steady-state due to fluctuations in supply and demand conditions. If the fluctuations are small, these are easily absorbed by the pipeline assisted by its long span and high compressibility of ethylene, and, accordingly the performance can be predicted reasonably well by a steady-state analysis. Abrupt changes to flow conditions resulting from a feed cut-off or compressor failure, for example, give rise to situations that should be analysed using a transient model. Therefore, a transient simulation model was incorporated to the system.

The operators communicate with the simulator interactively, via a simple interface assisted by a series of pull down menus. The various operating scenarios are modelled and grouped under modules. The module access, the definition of operating conditions, the run execution and the examination and analyses of results are all performed by the user through a menu-driven operating system.

The simulator design is based on an open architecture philosophy so as to allow fast and easy integration of future system expansion. Important areas in the pipeline operation are constantly being investigated, and accommodated as new modules.

The simulator operates in a stand-alone mode independent of the plant’s ‘Supervisory Control And Data Acquisition’ (SCADA) system, and accordingly presents an environment in which simulations under extreme operating conditions are carried out conveniently.

Pipeline Models

The simulator offers three models of the pipeline, describing the process at different levels of complexity. The simplest of these is the Small Model that returns ‘a quick estimate’ to an investigation. This model is often used in ‘What if’ case studies in which the user is more interested in a qualitative estimate of the plant’s response. The model includes all major process equipment such as compressors filters and meters.

A more detailed Medium Model of the pipeline includes all block valves and also the lines between the block valves. The model returns process conditions across compressors, filters, meters, block valves and line pipes. The results are more accurate but take longer computing times. More accurate pressure and temperature profiles give a better understanding to the status of the mainline, and at the same time provide a suitable basis for verifying the SCADA measurements. It determines line inventories to a high degree of accuracy.

Finally, the Large Model contains all the equipment described in the Medium Model but the main pipeline is represented by more individual pipe segments positioned between every significant local peak and trough. The computer time is heavy but the results are very accurate and informative. The Large Model is useful in applications requiring complete and smooth pressure and temperature profiles.

Role of Simulator in Pipeline Operations

The simulator takes an active participation in the pipeline operations in ensuring safety and economy. A necessary component of plant’s safety management is the training of operating personnel. Participants could experience the behaviour of pipeline under widely different operating conditions, the practical significance of operating limits and the manipulation of operating parameters for the optimal results. The applications can be laid down under the following general headings:

- Perform ‘What if’ case studies.

- Investigate safe operating limits.

- Process optimization.

- Planning and scheduling.

- Plant maintenance, shutdown and start-up.

- Plant modifications.

- Engineering design.

- Operator training.

References

- K.G.Bandara, “Interactive Simulation of the North Western Ethylene Pipeline”, European Ethylene Forum 1994, London, January 1994.

- Environmental Statement, the North Western Ethylene Pipeline, Shell Chemicals U.K. Limited Publication, 1988.

- North Western Ethylene Pipeline Project News, Shell Chemicals U.K, 1990.