Pipeline Modelling and Simulation

Pipeline simulation is a process of defining and solving a mathematical model of the transportation of fluid through a pipe. The model definition falls into two categories – for compressible and non-compressible fluids. The compressibility of a fluid is a measure of the relative volume change in response to a pressure change. Pipe flow in which variations in density are negligible are termed as incompressible flows. When density variations are not negligible flow is called compressible. The most common example of compressible fluid concerns the flow of gases, e.g. air and natural gasses, while the flow of liquids, e.g. water and oil, under low pressure are treated as incompressible. If there is not a significant change in density then flow as gases can be treated as incompressible.

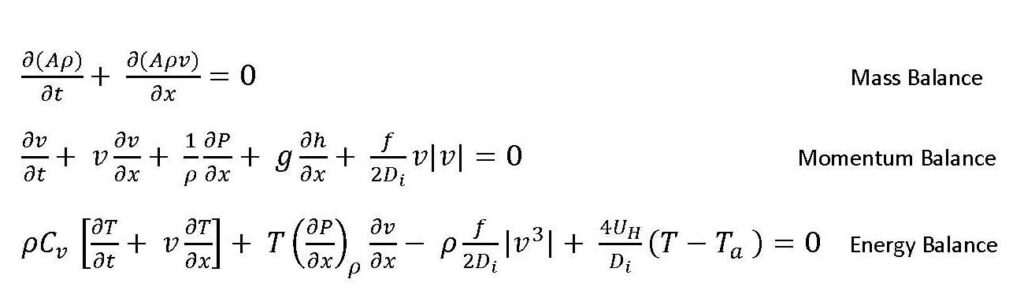

The modelling of pipeline assumes unidirectional flow and is formulated using the Navier–Stokes equation. The Navier–Stokes equation is an extension of the force acceleration model defined in the Newton’s second law which in this case is adapted to fluid motion. The flow of fluids in pipelines can be fundamentally represented by the Navier–Stokes momentum balance equation, the flow continuity governed by the mass balance equation and the thermal exchange governed by the energy balance equation. The momentum, mass and energy equations combined with the thermophysical properties of the fluid are solved simultaneously during the simulation.

Thermophysical relations for compressibility factor, density, enthalpy, and entropy, specific heats at constant pressure and volume, viscosity should be provided.

Nomenclature: A-pipe cross-sectional area, ρ-density, t-time, x-distance, v-velocity, P-pressure, T-temperature, Ta-ambient temperature, h-elevation, f-friction factor, Di-pipe internal diameter, UH-overall heat transfer coefficient, Cv-specific heat at constant volume.

Gas distribution pipelines are transportation systems with hundreds of kilometres of pipes accompanied by production stations, storage and distribution centres, compression stations, and many other devices like valves, meters, filters and regulators. The model should take into account the functionality of the field equipment and devices, pipe friction loss, elevation pressure change, heat transfer between the fluid and the surroundings, and the Joule-Thompson effect on the fluid.

Traditionally pipe pressure loss is the sum of three pressure difference components defined by hydrostatic pressure loss, frictional pressure loss and kinetic pressure loss. For most applications, kinetic losses are minimal and can be ignored. The frictional loss results from resistance of the fluid to movement. The pipe friction is represented numerically by a friction factor which is considered as the governing parameter of pressure loss equations used in industrial applications. Some of the conventionally recommended gas pipeline equations are found in the COLEBROOK, PANHANDLE A, PANHANDLE B, WEYMOUTH, BOYD and AGA equations. The friction factor found in the Navier-Stokes equation should be appropriately modified and iteratively refined so as to be able to complement the results of the traditional gas pipeline pressure loss equations.

The pipeline is defined by its length, diameter, elevation change, and wall thickness, overall heat transfer coefficient with the surroundings, ambient temperature, and fluid flow rate and conditions at inlet, outlet and take-off stations. The pipeline which has non-uniform characteristics is normally divided into pipe-legs having uniform characteristics for the ease of modelling and flow calculations.

During the analysis the pipe-leg is further subdivided into smaller segments called elements. The element length is chosen to suit the overall pipe length and the required accuracy of results.

For instance, a pipe-leg spanning a few kilometres of length carrying single phase fluid, the segment length of a few hundred meters should produce sufficiently accurate results for general industrial applications.

On the other hand, high pressure fluid discharging into let down pipes connected to a flare stack, for example, needs special attention. Rapid phase change and a steep temperature gradient can occur inside let down pipes and this fact must be taken into consideration in deciding the element length. In such situations, a smaller element length gives more accurate results.

Pipeline networks present a group of interconnected pipelines forming a set of nonlinear equations which are generally solved by methods employing an iterative procedure. Mass, pressure and energy is balanced at the nodes in line with the Kirchhoff’s first law. Simple networks made up of pipes arranged in closed loops the solution is achieved by the loop iteration method which should incorporate the node characteristics. The flow equations in this case are considered as a mathematical representation of Kirchhoff’s second law which states that the sum of the pressure-drops around any loop should be zero.

Simulators employ efficient finite-volume numerical methods modelling the flow in pipes. Each finite-volume takes the shape of a cylindrical element when modelling long pipe legs, and the shape of narrow disc elements for short pipe lengths. Each element is sequentially connected along the line by the finite-volume modelling techniques to solve the mass, momentum, energy equations and the fluid thermophysical properties. The solution is achieved by an iterative procedure in which the solver repeatedly computes a host of fluid properties and flow conditions such as, mass flow, pressure and temperature changes, density, phase and liquid fraction, enthalpy, entropy and heat capacities, heat transfer with the surroundings for each element until convergence.

Difficulties arise attaining the convergence during the processing of complicated networks as well as in accommodating the thermophysical properties of fluids sensitive to pressure and temperature. One requirement for smoothing out the convergence process is to use a suitable step damping or slope limiting procedure in the finite-volume solver.

The results obtained from the simulation of a high pressure ethylene pipeline are shown below. GBST Pipeline Simulator was used. The supply stream is 40 tonnes/hr of ethylene at 68 barg and 11 °C. The pipeline is of 0.25m internal diameter and 15.8km long rising uniformly from 24.4 to 137.2m. For this simulation an element length of 1000m is applied. The program rounded off the number of elements to 16 and the element length adjusted to 987.5m. Other pipe characteristics are shown in the results pages below. The NBS equation of state provided the thermophysical properties of ethylene.

The pipeline transports dense-phase ethylene which is a compressible fluid and classified as liquid when the temperature falls below the critical temperature line, and above the critical temperature line as vapour.

GBST Pipeline Simulator Ver 4.0 PAGE 3

USER: HELP DOCS [LicNo: GBST HELP]

PIPELINE EXAMPLE 06/12/2015

—————————————————————————————————————————————————————————————————————————————

P I P E R I G O R O U S A N A L Y S I S

—————————————————————————————————————————————————————————————————————————————

SPECIFICATIONS …

PIPELEG ID LINE510

DESCRIPTION PIPE SECTION NO. 510

HEADNODE ID SUPPLY

TAILNODE ID DELIVERY

FRICTION EQUATION COLEBROOK

EFFICIENCY 0.95

AGA DRAG FACTOR 0.15

HEADNODE ELEV 24.4

HEADNODE ELEV UNITS M

TAILNODE ELEV 137.2

TAILNODE ELEV UNITS M

PIPE LENGTH 15.8

PIPE LENGTH UNITS KM

PIPE ELEMENT LENGTH 1000

PIPE ELEMENT LENGTH UNITS M

PIPE INSIDE DIA 0.25

PIPE INSIDE DIA UNITS M

PIPE WALL THICK 7.25

PIPE WALL THICK UNITS MM

PIPE ROUGHNESS 100

PIPE ROUGHNESS UNITS MICRON

OVERALL U 10

OVERALL U UNITS W/M2/K

AMBIENT TEMPERATURE 5.4

AMBIENT TEMPERATURE UNITS C

OPERATING CONDITIONS …

—————————————————————————————————————————————————————————————————————————————

PROPERTY UNITS INLET LIQUID VAPOUR

————————————————— —————————————— ———————————— ———————————— ————————————

PIPELEG ID LINE510

HEADNODE OR IN STREAM ID SUPPLY

TAILNODE OR OUT STREAM ID DELIVERY

OUT STREAM SPLIT AS MOLPERCENT 100.000 0.000

PRESSURE BARA 69.01 63.84

TEMPERATURE DEG C 11.00 5.57

MOLECULAR WEIGHT KG/KGMOL 28.05 28.05

MASS FLOW KG/HR 4E+04 4E+04

VOLUME FLOW CUMETRS/S 3.27147E—02 3.11679E—02

DENSITY KG/CUMETRS 3.39636E+02 3.56492E+02

COMPRESSIBILITY FACTOR 2.4129E—01 2.16805E—01

ENTHALPY KJ/KG 7.25331E+02 7.04767E+02

INT. ENERGY KJ/KG 7.05011E+02 6.86858E+02

ENTROPY KJ/KG/K 5.58927E+00 5.52149E+00

SP HEAT (CP) KJ/KG/K 4.758 4.371

SP HEAT (CV) KJ/KG/K 1.505 1.477

CP/CV 3.162 2.959

VISCOSITY CP 0.041 0.045

PRESSURE GAIN/LOSS BARA —5.17

TEMP GAIN/LOSS DEG C —5.43

POWER GAIN/LOSS MW —2.2848E—01

PIPE LENGTH M 1.58E+04

PIPE ELEMENTS 16

ADJUSTED ELEMENT LENGTH M 9.875E+02

LINE PACK TONNES 2.73676E+02

—————————————————————————————————————————————————————————————————————————————

GBST Pipeline Simulator Ver 4.0 PAGE 4

USER: HELP DOCS [LicNo: GBST HELP]

PIPELINE EXAMPLE 06/12/2015

—————————————————————————————————————————————————————————————————————————————

P I P E R I G O R O U S A N A L Y S I S

—————————————————————————————————————————————————————————————————————————————

SPECIFICATIONS …

PIPELEG ID LINE510

DESCRIPTION PIPE SECTION NO. 510

HEADNODE ID SUPPLY

TAILNODE ID DELIVERY

FRICTION EQUATION COLEBROOK

EFFICIENCY 0.95

AGA DRAG FACTOR 0.15

HEADNODE ELEV 24.4

HEADNODE ELEV UNITS M

TAILNODE ELEV 137.2

TAILNODE ELEV UNITS M

PIPE LENGTH 15.8

PIPE LENGTH UNITS KM

PIPE ELEMENT LENGTH 1000

PIPE ELEMENT LENGTH UNITS M

PIPE INSIDE DIA 0.25

PIPE INSIDE DIA UNITS M

PIPE WALL THICK 7.25

PIPE WALL THICK UNITS MM

PIPE ROUGHNESS 100

PIPE ROUGHNESS UNITS MICRON

OVERALL U 10

OVERALL U UNITS W/M2/K

AMBIENT TEMPERATURE 5.4

AMBIENT TEMPERATURE UNITS C

PIPE ELEMENT OPERATING CONDITIONS …

———————————————————————————————————————————————————————————————————————————————

| PIPE ID | AMB T (C) | HEAD P(BARA) | HEAD H(KJ/KG) | DIFF P(BARA) |

| EL INDEX | FLOW(KG/HR) | TAIL P(BARA) | TAIL H(KJ/KG) | DIFF T(C) |

| EL LENG (M) | VISCOS(CP) | HEAD T(C) | DIFF H(KJ/KG) | DIFF ELV(M) |

| POSITION(M) | HEAD LIQ MOL%| TAIL T(C) | CP(KJ/KG.K) | LNPK(TONNES) |

| HEAD ELV(M) | TAIL LIQ MOL%| HEAD D(KG/M3)| CV(KJ/KG.K) | FRIC LS(BARA)|

| TAIL ELV(M) | HEAD PHASE | TAIL D(KG/M3)| CP / CV | TOTL LS(BARA)|

| ROUGHNESS(MM)| TAIL PHASE | VEL(M/S) | U (W/M2/K) | COMPRS (Z) |

———————————————————————————————————————————————————————————————————————————————

| LINE510 | 5.400 | 69.013 | 7.25331E+02 | —0.317 |

| 1 | 4E+04 | 68.697 | 7.21672E+02 | —0.839 |

| 987.50 | 4.18027E—02 | 11.000 | —3.6585E+00 | 7.05 |

| 0.00 | 0E+00 | 10.161 | 4.70313E+00 | 1.65492E+01 |

| 0.00 | 0E+00 | 339.636 | 1.50159E+00 | 4.81184E—02 |

| 7.05 | VAPOUR | 343.173 | 3.13 | —3.1655E—01 |

| 1E—01 | VAPOUR | 0.663 | 1E+01 | 2.39851E—01 |

———————————————————————————————————————————————————————————————————————————————

| LINE510 | 5.400 | 68.697 | 7.21672E+02 | —0.318 |

| 2 | 4E+04 | 68.379 | 7.18596E+02 | —0.726 |

| 987.50 | 4.23031E—02 | 10.161 | —3.0758E+00 | 7.05 |

| 987.50 | 0E+00 | 9.435 | 4.63376E+00 | 1.67053E+01 |

| 7.05 | 0E+00 | 343.173 | 1.49754E+00 | 4.78092E—02 |

| 14.10 | VAPOUR | 346.077 | 3.09 | —3.1799E—01 |

| 1E—01 | VAPOUR | 0.657 | 1E+01 | 2.37886E—01 |

———————————————————————————————————————————————————————————————————————————————

| LINE510 | 5.400 | 68.379 | 7.18596E+02 | —0.319 |

| 3 | 4E+04 | 68.059 | 7.16E+02 | —0.629 |

| 987.50 | 4.28165E—02 | 9.435 | —2.5965E+00 | 7.05 |

| 1975.00 | 0E+00 | 8.806 | 4.56636E+00 | 1.68337E+01 |

| 14.10 | 1E+02 | 346.077 | 1.49348E+00 | 4.75195E—02 |

| 21.15 | VAPOUR | 348.471 | 3.06 | —3.1937E—01 |

| 1E—01 | LIQUID | 0.652 | 1E+01 | 2.35807E—01 |

———————————————————————————————————————————————————————————————————————————————

| LINE510 | 5.400 | 68.059 | 7.16E+02 | —0.321 |

| 4 | 4E+04 | 67.739 | 7.13818E+02 | —0.543 |

| 987.50 | 4.32922E—02 | 8.806 | —2.1821E+00 | 7.05 |

| 2962.50 | 1E+02 | 8.263 | 4.50736E+00 | 1.69392E+01 |

| 21.15 | 1E+02 | 348.471 | 1.4898E+00 | 4.72555E—02 |

| 28.20 | LIQUID | 350.430 | 3.03 | —3.2064E—01 |

| 1E—01 | LIQUID | 0.648 | 1E+01 | 2.33789E—01 |

———————————————————————————————————————————————————————————————————————————————

| LINE510 | 5.400 | 67.739 | 7.13818E+02 | —0.322 |

| 5 | 4E+04 | 67.417 | 7.11992E+02 | —0.466 |

| 987.50 | 4.37105E—02 | 8.263 | —1.8258E+00 | 7.05 |

| 3950.00 | 1E+02 | 7.797 | 4.45853E+00 | 1.70252E+01 |

| 28.20 | 1E+02 | 350.430 | 1.48664E+00 | 4.70283E—02 |

| 35.25 | LIQUID | 352.020 | 3.00 | —3.2176E—01 |

| 1E—01 | LIQUID | 0.644 | 1E+01 | 2.31899E—01 |

———————————————————————————————————————————————————————————————————————————————

| LINE510 | 5.400 | 67.417 | 7.11992E+02 | —0.323 |

| 6 | 4E+04 | 67.094 | 7.10472E+02 | —0.399 |

| 987.50 | 4.40666E—02 | 7.797 | —1.5204E+00 | 7.05 |

| 4937.50 | 1E+02 | 7.399 | 4.41963E+00 | 1.70947E+01 |

| 35.25 | 1E+02 | 352.020 | 1.48401E+00 | 4.68394E—02 |

| 42.30 | LIQUID | 353.298 | 2.98 | —3.2269E—01 |

| 1E—01 | LIQUID | 0.642 | 1E+01 | 2.30152E—01 |

———————————————————————————————————————————————————————————————————————————————

| LINE510 | 5.400 | 67.094 | 7.10472E+02 | —0.323 |

| 7 | 4E+04 | 66.771 | 7.09212E+02 | —0.340 |

| 987.50 | 4.43629E—02 | 7.399 | —1.2596E+00 | 7.05 |

| 5925.00 | 1E+02 | 7.058 | 4.38965E+00 | 1.71502E+01 |

| 42.30 | 1E+02 | 353.298 | 1.48188E+00 | 4.66861E—02 |

| 49.35 | LIQUID | 354.311 | 2.96 | —3.2346E—01 |

| 1E—01 | LIQUID | 0.640 | 1E+01 | 2.2854E—01 |

———————————————————————————————————————————————————————————————————————————————

| LINE510 | 5.400 | 66.771 | 7.09212E+02 | —0.324 |

| 8 | 4E+04 | 66.447 | 7.08175E+02 | —0.290 |

| 987.50 | 4.46046E—02 | 7.058 | —1.0372E+00 | 7.05 |

| 6912.50 | 1E+02 | 6.768 | 4.36742E+00 | 1.71939E+01 |

| 49.35 | 1E+02 | 354.311 | 1.4802E+00 | 4.65642E—02 |

| 56.40 | LIQUID | 355.099 | 2.95 | —3.2407E—01 |

| 1E—01 | LIQUID | 0.638 | 1E+01 | 2.2705E—01 |

———————————————————————————————————————————————————————————————————————————————

| LINE510 | 5.400 | 66.447 | 7.08175E+02 | —0.325 |

| 9 | 4E+04 | 66.122 | 7.07327E+02 | —0.247 |

| 987.50 | 4.47976E—02 | 6.768 | —8.4797E—01 | 7.05 |

| 7900.00 | 1E+02 | 6.522 | 4.35178E+00 | 1.72275E+01 |

| 56.40 | 1E+02 | 355.099 | 1.47889E+00 | 4.64697E—02 |

| 63.45 | LIQUID | 355.697 | 2.94 | —3.2456E—01 |

| 1E—01 | LIQUID | 0.637 | 1E+01 | 2.25664E—01 |

———————————————————————————————————————————————————————————————————————————————

| LINE510 | 5.400 | 66.122 | 7.07327E+02 | —0.325 |

| 10 | 4E+04 | 65.797 | 7.0664E+02 | —0.210 |

| 987.50 | 4.49482E—02 | 6.522 | —6.8701E—01 | 7.05 |

| 8887.50 | 1E+02 | 6.312 | 4.34175E+00 | 1.72526E+01 |

| 63.45 | 1E+02 | 355.697 | 1.47792E+00 | 4.63984E—02 |

| 70.50 | LIQUID | 356.133 | 2.94 | —3.2492E—01 |

| 1E—01 | LIQUID | 0.636 | 1E+01 | 2.24367E—01 |

———————————————————————————————————————————————————————————————————————————————

| LINE510 | 5.400 | 65.797 | 7.0664E+02 | —0.325 |

| 11 | 4E+04 | 65.472 | 7.06089E+02 | —0.178 |

| 987.50 | 4.5062E—02 | 6.312 | —5.5033E—01 | 7.05 |

| 9875.00 | 1E+02 | 6.134 | 4.33648E+00 | 1.72704E+01 |

| 70.50 | 1E+02 | 356.133 | 1.47724E+00 | 4.63468E—02 |

| 77.55 | LIQUID | 356.433 | 2.94 | —3.2519E—01 |

| 1E—01 | LIQUID | 0.635 | 1E+01 | 2.23144E—01 |

———————————————————————————————————————————————————————————————————————————————

| LINE510 | 5.400 | 65.472 | 7.06089E+02 | —0.325 |

| 12 | 4E+04 | 65.147 | 7.05655E+02 | —0.151 |

| 987.50 | 4.51442E—02 | 6.134 | —4.3418E—01 | 7.05 |

| 10862.50 | 1E+02 | 5.983 | 4.33526E+00 | 1.72821E+01 |

| 77.55 | 1E+02 | 356.433 | 1.4768E+00 | 4.6312E—02 |

| 84.60 | LIQUID | 356.616 | 2.94 | —3.2537E—01 |

| 1E—01 | LIQUID | 0.635 | 1E+01 | 2.21985E—01 |

———————————————————————————————————————————————————————————————————————————————

| LINE510 | 5.400 | 65.147 | 7.05655E+02 | —0.325 |

| 13 | 4E+04 | 64.821 | 7.0532E+02 | —0.128 |

| 987.50 | 4.51993E—02 | 5.983 | —3.3558E—01 | 7.05 |

| 11850.00 | 1E+02 | 5.855 | 4.33751E+00 | 1.72885E+01 |

| 84.60 | 1E+02 | 356.616 | 1.47656E+00 | 4.62915E—02 |

| 91.65 | LIQUID | 356.700 | 2.94 | —3.2547E—01 |

| 1E—01 | LIQUID | 0.635 | 1E+01 | 2.20878E—01 |

———————————————————————————————————————————————————————————————————————————————

| LINE510 | 5.400 | 64.821 | 7.0532E+02 | —0.326 |

| 14 | 4E+04 | 64.496 | 7.05068E+02 | —0.109 |

| 987.50 | 4.52311E—02 | 5.855 | —2.5178E—01 | 7.05 |

| 12837.50 | 1E+02 | 5.746 | 4.34275E+00 | 1.72906E+01 |

| 91.65 | 1E+02 | 356.700 | 1.47651E+00 | 4.62829E—02 |

| 98.70 | LIQUID | 356.699 | 2.94 | —3.2552E—01 |

| 1E—01 | LIQUID | 0.635 | 1E+01 | 2.19816E—01 |

———————————————————————————————————————————————————————————————————————————————

| LINE510 | 5.400 | 64.496 | 7.05068E+02 | —0.326 |

| 15 | 4E+04 | 64.170 | 7.04887E+02 | —0.093 |

| 987.50 | 4.52431E—02 | 5.746 | —1.8054E—01 | 7.05 |

| 13825.00 | 1E+02 | 5.653 | 4.35059E+00 | 1.72888E+01 |

| 98.70 | 1E+02 | 356.699 | 1.4766E+00 | 4.62847E—02 |

| 105.75 | LIQUID | 356.626 | 2.95 | —3.2551E—01 |

| 1E—01 | LIQUID | 0.635 | 1E+01 | 2.18791E—01 |

———————————————————————————————————————————————————————————————————————————————

| LINE510 | 5.400 | 64.170 | 7.04887E+02 | —0.325 |

| 16 | 4E+04 | 63.845 | 7.04767E+02 | —0.079 |

| 987.50 | 4.52381E—02 | 5.653 | —1.199E—01 | 7.05 |

| 14812.50 | 1E+02 | 5.575 | 4.3607E+00 | 1.72838E+01 |

| 105.75 | 1E+02 | 356.626 | 1.47683E+00 | 4.62952E—02 |

| 112.80 | LIQUID | 356.492 | 2.95 | —3.2546E—01 |

| 1E—01 | LIQUID | 0.635 | 1E+01 | 2.17798E—01 |

———————————————————————————————————————————————————————————————————————————————